What is the most crucial aspect in wheels manufacturing? We see it as a mix of science and art. Combine it with continuous innovations and multistage quality check and you will get the best product .

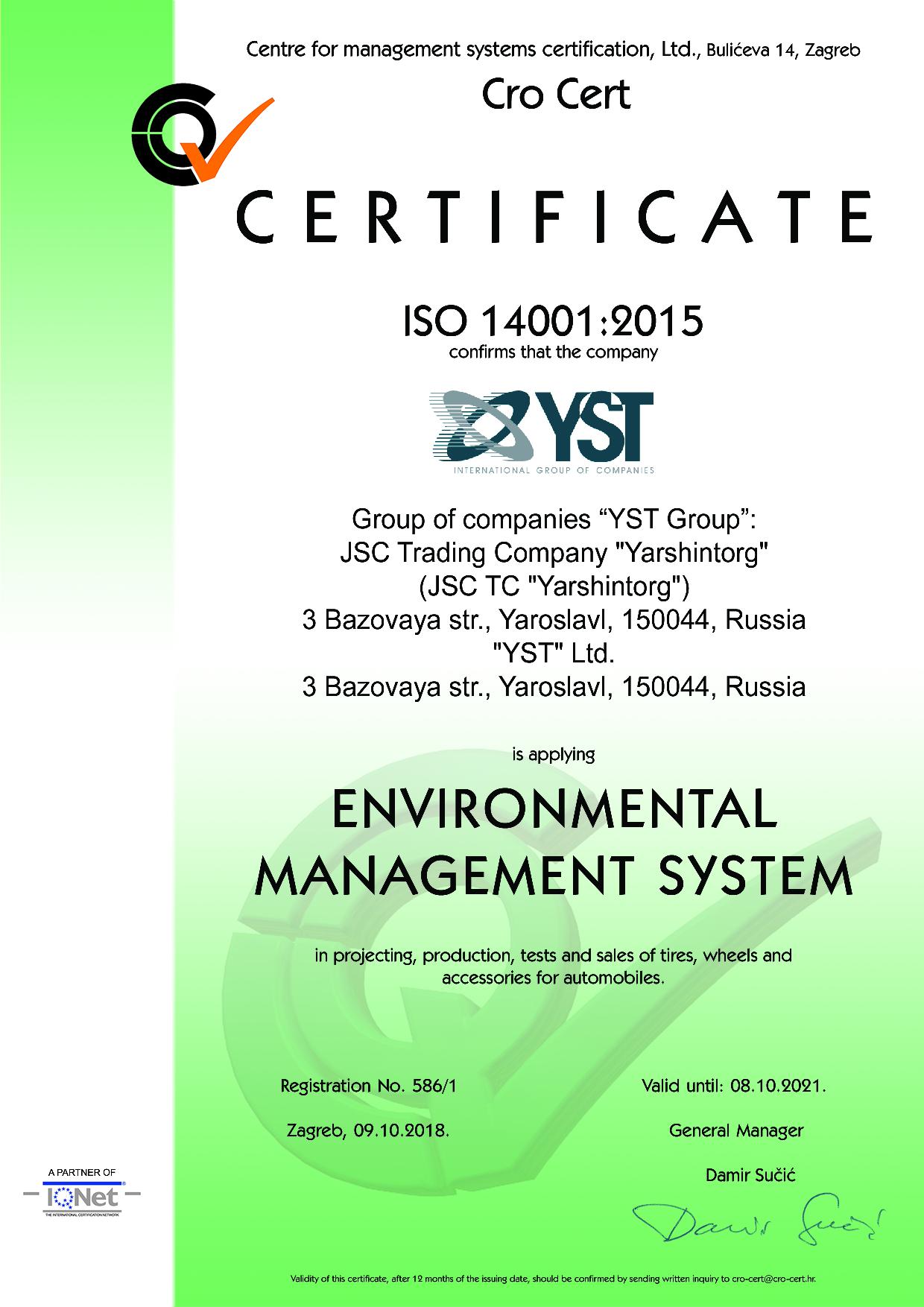

Production capacities entail 4 modern full-cycle plants: 2 alloy wheels plants with total output of 2 million units per year and 2 steel wheels plants producing 1.5 million units per year. Each plant meets all the requirements of ISO 14001:2004, ISO/TS 16949, ISO 9001:2008. All products have certificates of compliance TSE, CE.

Wheels are designed and manufactured only by highly professional designers and engineers. Thanks to our recruitment system, we are always able to build a team of qualified best-in- class specialists and experts.

We know everything about a wheel long before it is casted. Development of each model begins with a virtual mold simulation. Engineers design a 3D model and then take it through all types of virtual tests. Software allows us to forecast, how a wheel will act on test benches. When a 3D model is approved, we are sell a tryout batch, which is tested under real conditions.

New model’s life cycle starts with mold casting. Our alloy and steel wheels are manufactured from raw materials of the highest quality from our trusted suppliers. Raw materials for steel wheels are supplied by Baosteel Group, worldwide renowned metallurgic giant.

Main alloy components are molten aluminum, silicon and alloying additives. In the process of production, we use aluminum cast alloy combined with T6 heat-treatment technology. It has the best heat-treatment resistance and 20% better resistance to mechanical impacts. When it’s ready, a tryout sample goes to spectral analysis to be checked for compliance with all regulations and standards.

Wheels are casted with 2 methods: low-pressure and gravity die casting. With our 25 7-axis automatic low-pressure casting stations and 20 gravity die casting machines, we ensure complete mold filling and tight alloy’s microstructure. Manufactured castings then undergo an X-ray check to exclude any internal defects.

Highly accurate NC machines are able to cast and do the mechanical processing of any wheels sizes from 12 to 30 inches. We can also easily launch a required mold upon customer’s request.

Paint lines of factory installed at plants are equipped with the cutting-edge equipment from Italy. In production process, factory use environment-friendly powder paints, which uniformly apply to wheel’s body improving the paintwork quality on even surfaces, sharp angles and edges. This method ensures high throwing power and absence of sagging, paint defects or orange peel.

Thanks to high covering power of powder paints, wheels look great and resist to chemicals and mechanical impacts for years.

Steel wheels are manufactured from sheet metal supplied in coils. These coils are unrolled and cut separately for each wheel size. Each workpiece goes through roll-forging, pressing and welding to become a semi-finished product, which is then profiled and given the shape of a wheel’s rim.

At the assembly line, wheel spokes are pressed into the rim and welded with 4-stroke CO2 spot welding. A finished wheel is checked according to quality requirements and covered with protective and decorative coating.

Before they are released from production, wheels go through all kinds of quality checks on test benches in our own laboratory: test for tension, radial runout, dynamic balancing, tightness, corrosion resistance, structural integrity, micro cracks, chromatic control and paint adhesive properties.

YST Group guarantees its customers the unrivalled quality and stable consumer properties at 99.3% during the whole wheel’s lifetime of the wheel.

In 2016, construction of a new stamped wheels plant kicked off in Yaroslavl. Backed by YST Group as a main investor, the wheels production facility was built and launched on the investor’s premises within a short time. Thus, at the end of 2017, the first full-cycle plant for production of stamped wheels for passenger cars and LCVs began to operate in Yaroslavl.

The plant creates a developed industrial infrastructure around its premises.

All manufacturing processes are highly automated with the line equipment supplied from Italy, USA, China and Russia. Production capacity is 1.5 million wheels per year. The plant produces 13", 14", 15", 16" and 17" wheels for all popular automotive brands. This new facility also allows us to relocate the flow of goods from China to Russia. We already deliver finished products to Russian OEMs, which will install our wheels on their vehicles as standard, and signed contracts for wheels export to Europe. All wheels produced in Russia comply with the German TUV and Italian Qualilab standards. The production meets a range of ISO 9001 international standards, while reliability of final products complies with regulations applied in Russia, North America, Europe and Asia.

The social importance of this new plant can be clearly seen already today with dozens of engineers and operators engaged in the manufacturing process. The production facility creates over 150 new jobs and improves the welfare and economic situation in the region.

Besides our commitment to cost-efficient production, we are implementing environmental sustainability approach. We have developed a long-term program to reduce emissions of the new plant, which includes international standards and environmental monitoring systems.

All this allows us to adjust production load in real time and keep emissions within permissible limits.

The Yarshintorg company is a production site of custom-built forged wheels. We manufacture the wheels according both to individual customer designs and ready-made design solutions created by our designers. Our products can be found among the models of forged wheels of well-known brands. We cooperate with domestic and international companies; moreover we make well-run supplies to the CIS and Europe countries.

For produсtion of forged wheels we use T6061 aluminum-based alloy with alloying additives of magnesium, copper, silicium, zinc and other metals. This alloy is applied in production of components for aircraft industry.

Each client is individually consulted. Our personal managers guide a manufacturing process from the beginning to the end, which ensures high quality of the product and timely execution of work.